Oxidation, complex Oxidation Processes

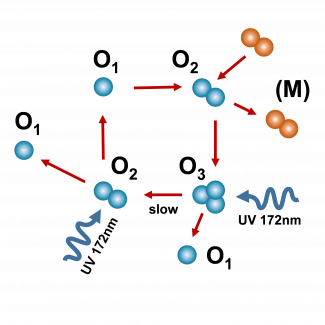

By irradiation with VUV 'old' chemical bonds break up, new ones can be made. Thus, in this process, e.g. in air or pure oxygen very efficiently ozone and free oxygen radicals are generated, which in turn can oxidize other substances.

By irradiation with VUV 'old' chemical bonds break up, new ones can be made. Thus, in this process, e.g. in air or pure oxygen very efficiently ozone and free oxygen radicals are generated, which in turn can oxidize other substances.

The resulting 'wast products' CO2 and H2O (water) are non-toxic and easily volatile.

Since the 7,2 eV energy of the photons is not sufficient for splitting nitrogen molecules N2, toxic nitrogen oxides NOx cannot develop, as they occur in many plasma processes. Nitrogen can therefore be used as purge gas.

The combination of ozone and UV radiation has a particularly oxidizing effect, since not only the binding energy of the ozone but also the radiant energy is available at the same time. This is e.g. interesting for semiconductor processing or oxidation. It can be e.g. produce high-density oxide layers at low temperatures.

Surface Cleaning, Activation and Sterilisation![Xeradex blau]()

Transport, storage and last but not least production processes leave traces on the adjacent surfaces. These may be water adherences, as well as organic substances such as e.g. greases, oils or release agents.

Contaminated surfaces often need to be stripped of this layer for further processing. This can be the mold release agent in the plastic production as well as the water skin in semiconductor manufacturing. This is possible with VUV radiation over a large area.

Other surfaces that shall be glued or printed, for example, must be prepared accordingly so that - to stick to the example - adhesive, plastic coating or paint adhere, spread well. This increase in surface energy is also possible over a large area with VUV radiation.

- operation at standard pressure

- at normal temperature

- without solvents, primer or cleaning agents (no chemicals, no toxic waste)

- when applied in air no NOx

- wide application possibilities: suitable for LCD screens as well as for solar cells or various plastics

- soft on surfaces (no material loss)

- simple process, no secondary processes needed (e.g. post processing)

- saves time and energy

Hardening and Matting of Lacquers (Polymerisation)

The matting of UV-curing acrylate coatings using matting agents involves various difficulties. Thus, larger additions of matting agents increase the viscosity excessively. Very low gloss levels are so impossible to achieve.

The matting of UV-curing acrylate coatings using matting agents involves various difficulties. Thus, larger additions of matting agents increase the viscosity excessively. Very low gloss levels are so impossible to achieve.

172 nm excimer radiation offers an alternative here.

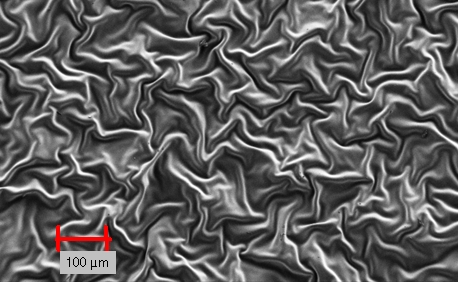

The 172nm - radiation does only penetrate the outermost layer of a freshly applied lacquer coating and shrinks that by polymerisation. Afterwards, the whole coating is hardened through/ cured by longer waved UV radiation (200 - 400 nm).

This results in a 'drapery'-surface - visible in the microscopic view, which achieves very low gloss levels and does also have outstanding haptic properties.

The resulting surface is characterized by excellent resistance to mechanical and chemical stress.