High-Energy UV for Precision Applications

Vacuum ultraviolet radiation, or VUV for short, is a particularly high-energy range of electromagnetic radiation. It plays a central role in materials processing, semiconductor technology, and analytical measurement technology. Due to its short wavelength, it offers unique possibilities for surface modification and chemical activation. In this article, we examine the physical principles, applications, and advantages of VUV radiation.

Fundamentals of VUV Radiation

VUV stands for vacuum ultraviolet radiation and refers to the spectral range of ultraviolet radiation with wavelengths between 100 nm and 200 nm.The name derives from the fact that this radiation is quickly absorbed in air and can only propagate in a vacuum or in special noble gas atmospheres.

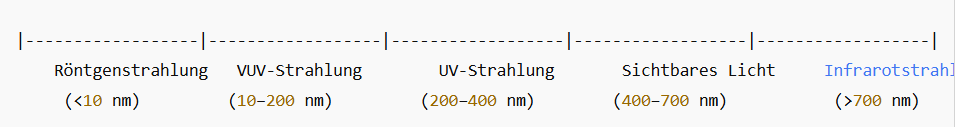

VUV spectrum in the electromagnetic spectrum:

Typical sources of VUV radiation are:

- Excimer lamps (e.g., xenon at 172 nm)

- Gas discharge lamps (e.g., deuterium lamps)

- Synchrotron radiationfor research and analysis

VUV photons have high energy (up to over 10 eV) and can break chemical bonds, eject electrons from atoms, or functionalize surfaces – without thermal effects.

A key characteristic: The radiation penetrates materials only a few nanometers deep, enabling extremely close-to-surface effects.

Areas of Application and Materials

VUV radiation is primarily used in highly specialized industries and research institutions. The most important application areas include:

- Surface Activation and Cleaning: VUV radiation selectively alters the chemical structure of the outermost layer of a material, e.g., to improve adhesion properties in plastics, glass, or semiconductors.

- Plasma Technology and Photochemistry: The high photon energy is ideally suited for photoinitiated reactions, e.g., in the production of plasmas, plasmas, and plasmas. B. in semiconductor manufacturing or surface functionalization.

- Analytical Methods: In photoelectron spectroscopy (UPS) or mass spectrometry, VUV is used for excitation or ionization.

- Medical and Environmental Technology: Germ reduction and disinfection using VUV radiation are particularly effective due to the high energy and short penetration depth – e.g., in water treatment or cleanroom environments.

Suitable materials for irradiation include plastics, quartz glass, silicon, metal oxides, and technical glasses. A controlled environment (vacuum, nitrogen, or noble gases) is essential to prevent absorption losses.

Advantages of VUV Technology

Extremely shallow penetration

Due to its shallow penetration depth, VUV radiation can selectively influence the outermost molecular layers – without damaging the underlying material. Ideal for sensitive substrates.

High photon energy

VUV photons possess sufficient energy to break stable chemical bonds or excite electrons. This opens up diverse possibilities in photochemistry and microstructuring.

Chemical-free surface modification

Processing with VUV radiation can be carried out without aggressive wet chemicals – environmentally friendly and residue-free. This is particularly relevant for applications in medicine and the use of VUV radiation in semiconductor technology.

Precise Controllability

VUV emitters such as excimer lamps enable defined radiation doses at precisely known wavelengths – ideal for reproducible processes in research and industry.

Conclusion: VUV Radiation as a Precise Tool for the Microworld

VUV radiation combines maximum energy with minimal penetration depth – an ideal combination for precise surface treatment, activation, or analysis. Whether in electronics, environmental technology, or materials research: This technology offers powerful solutions for challenges where conventional UV or IR radiation reaches its limits.

Learn More

Radium TECH offers specialized excimer lamps for the VUV range – contact us today for a consultation on individual application scenarios and process solutions!