UV

UV Emitters from Radium TECH

Your powerful tool for surface treatment

Radiation with sufficient energy has the ability to crack chemical bonds. Vacuum UV (VUV), i.e. UV radiation below 200 nm, is particularly energy-rich.

Radiation with sufficient energy has the ability to crack chemical bonds. Vacuum UV (VUV), i.e. UV radiation below 200 nm, is particularly energy-rich.

Thus, it is able to clean surfaces from organic contaminations by destroying their internal structure. The ability to destroy organic bonds can also be used to etch plastic surfaces, even PTFE, or to initiate chemical reactions. This includes the curing of UV varnishes in the printing industry. In special cases, it is even possible to do without starter molecules.

VUV also splits the oxygen in the air and can be used to generate ozone and activated oxygen very effectively and locally for various purposes. Surfaces such as silicon wafers or other materials can be oxidized with very high quality. Simultaneous irradiation with UV light allows high-quality oxide layers to be created within a very short time at low temperatures.

VUV radiation also increases surface energy and wettability, thus contributing to improved adhesion, for example.

UV-C radiation in the 254 nm range, on the other hand, is energetic enough to destroy bacteria, viruses, and fungi, but does not produce potentially harmful ozone. This makes it ideal for disinfection.

Why Radium TECH?

Radium TECH offers ultraviolet lamps for industrial production processes in various wavelength ranges and designs. This allows our UV solutions to be integrated into both existing and new production processes – with the 'Made in Germany' label.

In addition to our range of versatile excimer lamps, we also create customized solutions for our customers. With over 35 years of experience in the development and production of industrial infrared, UV, and other special lamps, we are your reliable partner.

Our UV Lamps Product Portfolio

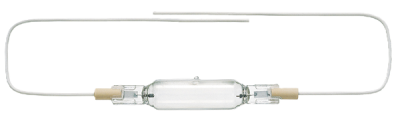

XERADEX® Excimer Emitters

Our XERADEX® excimer lamps operate in the short-wave vacuum UV (VUV) range. They ensure efficient and gentle surface treatment – for example, in the furniture and semiconductor industries or in ultrapure water production.

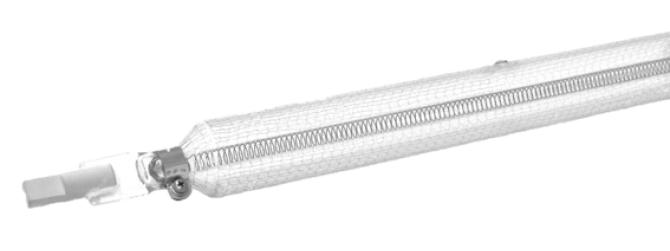

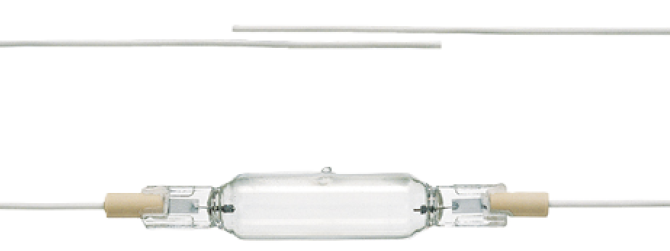

UV High Pressure Lamps Suprasol

Our Suprasol HTC lamps are extremely powerful radiation sources that emit a broad spectrum of UV light with very high intensity. Thanks to their spectral composition, they are suitable for both photochemistry and surface modification. They are also used in phototherapy and photochemotherapy for the treatment of skin diseases, as well as for effective tanning (pigmentation).

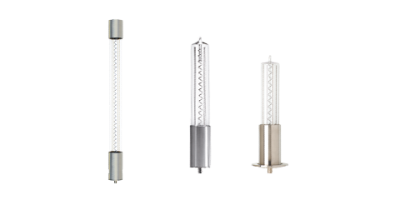

UVC T8 254 nm

Our 254nm UV-C low-pressure lamps emit their mercury line radiation primarily in the short-wave ultraviolet range. This process ensures effective, chemical-free, and environmentally friendly disinfection in a wide variety of areas. Various power levels and sizes are available depending on the application.

Your Message to us

Do you have questions about our selection of infrared heaters, need a quote, or need advice on a customized project? Contact our experts at the Radium TECH Application Center now. We're happy to help!

Radium TECH Application Center

Need any support with your customized UV or IR solution? Our experts are happy to help!

Operating Unit for Testing

or other specific request?

Whether specific emitter products or test module(s) for XERADEX® UV emitters for Radium TECH prototypes:

Please enter your equipment requirements in the "Other" section of the form.

Thank you!

Excimer Technology

How does it work? What can it be used for?

Excimer technology for precise surface treatment.