In various manufacturing processes, surface optimization is crucial for product quality. Excimer technology has established itself as an advanced method for surface treatment. Its strengths lie in the highly effective and precise preparation and activation of material layers. Since the generated UV radiation carries virtually no heat energy, heat damage is also eliminated. The high photon energy can, in turn, break many bonds. In this article, we explain the fundamentals, advantages, and industrial applications of excimer technology.

Basics of Excimer Technology

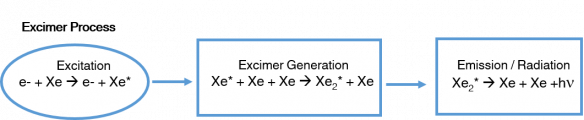

Excimer technology is based on the formation of unstable, excited gas molecules (so-called excimers), which are generated by an electrical discharge. During their rapid decay, they release energy in the form of high-energy radiation—high-energy photons—within a narrow wavelength range.

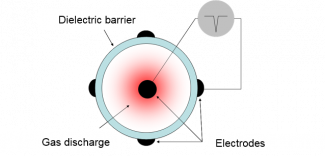

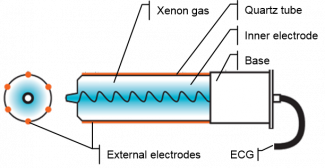

Various noble gases or noble gas halide compounds can be used, each emitting characteristic, usually spectrally narrowly limited radiation, such as xenon (172 nm), krypton chloride (222 nm), xenon iodide (253 nm), or xenon chloride (308 nm) are used. A dielectric barrier discharge (DBD) is used to excite the excimers between an inner electrode and the outer electrodes on the gas-tight glass vessel.

An alternating voltage in the range of several thousand volts is used for excitation. The pulsed alternating voltage used by Radium TECH increases the efficiency of xenon to approximately 40 percent.

Excimer emitters allow the treatment of upper material layers without damaging underlying layers; the penetration depth of the radiation depends primarily on the substrate properties. Since the generated UV radiation carries virtually no heat energy, heat damage is also impossible. This makes excimer technology particularly valuable for processing sensitive materials.

Applications and Materials

Excimers are also used in gas lasers, the so-called excimer lasers. In these, the laser-active medium consists primarily of noble gas halides (i.e., actually exciplexes), which allows the generation of electromagnetic radiation in the ultraviolet wavelength range. A well-known application is laser eye surgery in medicine. However, excimer lasers should not be confused with the excimer lamps discussed here.

In practice, excimer lamps are frequently used in furniture and flooring manufacturing for the matting of lacquers. They are also used in microchip manufacturing, for cleaning medical devices, and for optimal adhesion of lacquers and coatings. Excimer lamps can be used to treat workpieces made of materials such as plastic, metal, and glass.

The high energy of the photons allows for the creation of specific surface textures that are crucial for further processing in the manufacturing process or for the end use. This results in the versatility and efficiency of the technology in various industrial scenarios. In addition to creating textures, the UV cleaning effect is sometimes also desired.

Advantages of Excimer Technology

Optimization of Manufacturing Processes

Excimer technology allows, for example, acrylic lacquers to be matted without matting agents, which improves durability and surface finish. The radiation is immediately usable without heating and can be switched off, which optimizes efficiency and energy consumption. You can find more information on this topic under Excimer Matting.

Improved Surface Activation

By preparing the surface structure, the adhesive forces at the contact surfaces of materials (so-called adhesion properties) can be improved. UV surface activation is useful in the automotive and aerospace industries, where strong and durable bonds are particularly important.

Protection of sensitive surfaces

A key advantage of excimer technology is its ability to precisely treat sensitive surfaces without damaging them. This is crucial in the electronics and semiconductor industries, where material integrity is essential for functionality.

Efficient surface cleaning

Excimer UV technology also enables efficient surface cleaning by removing contaminants and oxide layers. This not only improves the aesthetics but also the durability of components, machines, or materials.

Conclusion: Versatile Excimer Lamps

As this article demonstrates, excimer technology combines many advantages for surface treatment in various industries. Its ability to precisely and gently process or clean sensitive materials makes it a valuable tool. The technology facilitates efficient and high-quality manufacturing. Here at Radium Tech, we offer various xenon excimer lamps and also manufacture excimer lamps with other excimers and thus different wavelengths.

Learn more

Contact our experts to discuss your individual application scenarios!