The simulation of sunlight is an indispensable tool for testing materials and components under controlled, reproducible conditions. Whether in automotive, photovoltaic, or materials research – solar simulation enables standards-compliant aging and stress tests, regardless of time of day, weather, or season.

Technical Principles of Solar Simulation

The natural solar spectrum at Earth's surface ranges from approximately 300 nm to about 4,000 nm and includes UV, visible, and infrared radiation. For reproducible test conditions, spectral distributions have been defined in standards such as DIN 75220, MIL-STD 810, IEC 68, IEC 61215, and IEC 61646.

Various light sources are used in modern solar simulation systems:

- Metal halide lamps (Radium HRI) – daylight-like spectrum, high efficiency, suitable for large-area illumination.

- Xenon lamps – best spectral matching in the UV and visible ranges, especially for precise laboratory simulations.

- High-pressure UV lamps (e.g., Radium Suprasol HTC) – targeted UV components for specific material tests.

- IR lamps – when thermal radiation is the primary requirement. will be.

Application – from Automotive Testing to Photovoltaics

Automotive Industry

- Climate chambers for component and vehicle system testing

- Material aging and emission tests

- UV preconditioning and heat tests for paints, seals, and plastics

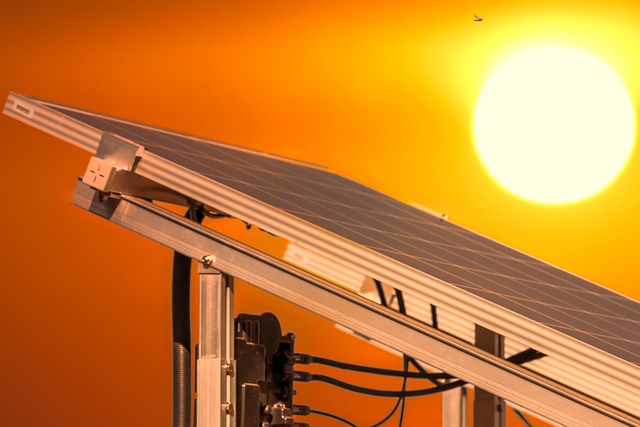

Photovoltaics

- Long-term tests for PV modules according to IEC 61215 / IEC 61646

- Light soaking, hotspot tests, UV pretreatment

Material and Coating Tests

- Determination of color and gloss changes (fading)

- Embrittlement, deformation, and loss of mechanical strength

- Testing of textiles, plastics, paints, and adhesives

Advantages of Artificial Solar Simulation using Light Sources compared to Field Tests

- Reproducibility: Identical conditions for comparative tests

- Acceleration: Long-term effects can be simulated within a few days

- Conformity to standards: Fulfillment of international testing standards

- Flexibility: Combination with temperature, humidity, and altitude profiles

- Safety: Targeted control of irradiance intensity

Conclusion: Reliable Test Results for the highest Quality Standards

Whether automotive supplier, PV manufacturer, or materials laboratory – solar simulation is the key to reliable, comparable results Test results. With our experience in developing high-performance lamp systems, we offer you customized solutions to optimize your testing processes.

Looking for a development partner? Our experts can help.

For every application, careful testing of material requirements and process parameters is essential. The methodology is also constantly evolving, offering new opportunities for industries seeking a competitive edge in surface finishing technology. Our experts from the Radium TECH Application Center are available to support you in your development projects. On the path to new solutions in industrial UV and IR applications!